The Importance of Lintels in Construction

In case you

are wondering, the lintel is a type of beam supporting the structures above

openings such as windows, doors, cupboards etc.

Two main Importance of Lintels:

I. The primary function of the lintel is to distribute the weight of the

above structures on the side walls.

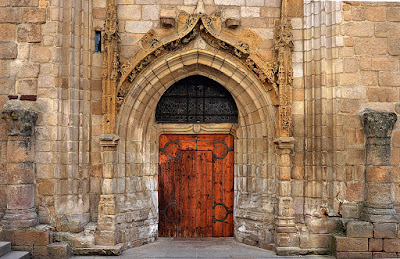

II. It also serves as a decorative element in many masonry designs.

Classification of Lintels:

Wooden lintels - these are used on

areas with an abundant supply of lumber and the oldest type.

Wooden

lintels are rarely used now because it's costly, may catch fire easily, decay

and susceptible to termites.

Commonly

used wooden lintels are teak and rosewood.

Stone lintels - sturdier than wooden lintels

and commonly used on stone masonry structures.

Stone

lintels are not commonly used today due to:

costly for

quarrying

cannot

withstand transverse stresses

transport,

dressing and handling is difficult due to its weight

Brick lintels - generally made up of

hard, well- burnt, free of defects such as lumps and cracks are used on small

openings (less than a meter) with a lighter load.

Bricks on

end, on edge or course horizontal, are its usual forms laid over openings.

Bricks with frogs filled with mortar provide better resistance at joints than

regular bricks.

Reinforced brick lintels - same as

brick lintels but reinforced with steel bars in the middle.

This lintel

covers a wider area. The spaces in between are covered with cement or concrete

mortar.

Not

recommended on areas with lots of rain or humidity since it erodes the

material.

Concrete lintels - the most widely used

lintel in today's construction. The material used is cement concrete.

Two types:

·

Plain

concrete - prepared with pure concrete. They are not useful for heavy

loads. Used for a span of only one meter. Strong in compression and weak in

tension forces.

·

Reinforced

concrete - also known as RCC, is the best type of lintel to use. It is

durable, strong, and fire resistant.

Reinforced with

a steel bar in the middle, RCC can be used in wider spans of construction.

Pre-cast RCC is used if speed is needed in development.

Steel lintels - when the depth of a

lintel is restricted on a large span, engineers

usually use steel lintels. These lintels can support heavy loads such as

used on storefronts, bay windows and areas with smaller but more massive load.

Though very good in compressive and tensile strength better than RCC, steel has

some disadvantages.

o

Concrete usually stops the spread of fire;

that's why RCC is used in areas where heat is present. Steel lintels can lose

its integrity when exposed to extreme heat and therefore dangerous for it will

lose its weight bearing capacity.

o

Cold bridging is also to consider when using

steel lintels. Concrete can reduce cold bridging and is a better insulator than

steel.

o

Steel can corrode easily whenever moisture and

certain chemicals are present. Some steel also reacts to sea salt, but

stainless steel can be a good option when used in these areas.

o

The cost is also a determinant when looking for

lintels. Concrete is generally much more affordable than steel; that's why this

is the most commonly used in construction.

VIDEO PRESENTATION

FIND US ON

https://www.galintel.com.au/

|

No comments:

Post a Comment